This business overview outlines why the information standard (ISO 10303-239, PLCS) addressing product life cycle support can reduce costs and improve profits for:

- any stakeholder with a role in specifying, designing, manufacturing, operating or supporting complex assets such as aircraft, weapons systems and infrastructure projects;

- at any level in the supply chain;

- at any stage in the life cycle.

In September 1999 the Harvard Business Review published an article by Richard Wise, Peter Baumgartner encouraging manufacturers, whose margins were under increasing pressure from global competition, to "Go Downstream" to maximize earnings over the life cycle of their products.

OEMs are ideally placed to exploit after-market opportunities,

for instance, in the defence sector,

where customer 'pull' now matches supplier 'push' through Government initiatives

promoting ever greater involvement of industry in after-market activities,

including support to operations and ongoing upgrades.

Major drivers for this change include Performance Based Logistics contracts,

being placed by DoD, and the

UK Defence Industrial Strategy and the related

Through Life Capability Management initiative.

Norway and Sweden are also moving strongly in the same direction.

and the related

Through Life Capability Management initiative.

Norway and Sweden are also moving strongly in the same direction.

A key requirement for after-market success is the ability to accurately and efficiently manage the complex information related to product design, operation and support over timescales measured in decades. The information standard ISO 10303-239 Application Protocol: Product Life Cycle Support PLCS was created to address this need. It was developed jointly by a commercial consortium of owner operators, OEMs and software vendors, including ministries of Defence from UK, US, Norway, Finland and Sweden; Boeing, Lockheed Martin, BAE Systems, Rolls Royce, Saab and DNV plus PTC, EDS, Baan, IFS, Pennant ATI, Eurostep Limited and the LSC Group. Subsequent work has created standard Data Exchange Specifications (DEXs) that will greatly facilitate the implementation of PLCS, and hence to realize the benefits described above.

Companies engaged in managing complex assets through time face several information management challenges:

- Much of the data needed to deliver successful support derives from the product design and manufacturing processes, where support information requirements are rarely a primary focus

- Support activities cross many system and organizational boundaries, making it difficult to impose a "single application" solution for data collection and consolidation

- Obsolescence, upgrades and changes to the operational context can create major problems in maintaining alignment between the configuration of actual assets and that of the technical data which specifies necessary support

- Optimization of support delivery, and the operation of performance management depend crucially on the capture of adequate feedback from the in-service domain

- The significance of such feedback is often dependent on context, yet many of the relationships which provide such context - for example, the nature of the mission just competed, or the precise configuration of the asset in question - are lost when feedback is captured

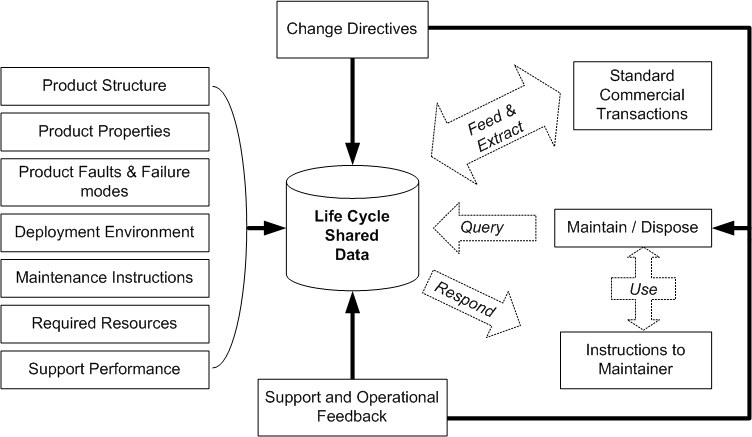

The goal of PLCS was to create an internationally accepted information model - likely to remain valid for several decades - to enable open information exchanges, and necessary data consolidation to address the issues above. This goal is summarized by Figure 1.

The initials "PLCS" were conceived in 1996 but the development of a community of interest with sufficient resources and credibility to develop the standard itself took some time to emerge. Work came to fruition in 1999, customers, suppliers and their system vendors recognized the relevance of STEP and provided the impetus around which a not-for-profit company "PLCS, Inc." was formed to develop ISO 10303-239 as an extension to the ISO 10303 STEP standard. ISO 10303-239 drew heavily from, and contributed to, the work within STEP to develop a harmonized data schema for Product Data Management. ISO 10303-239 was published as a full International Standard in 2005. ISO 10303-239 edition 2 that extends the original scope and provides better hrmonization with other STEP standards (such as the Systems Engineering standard AP233) is due for publication in 2011.

Although PLCS, Inc. disbanded in 2004 when the standard was delivered to ISO, work has continued since publication under the PLCS Technical Committee of OASIS. The move to OASIS was consciously made to engage directly with the wider XML community, and the evolving information technologies used for exchange.

The business scope of PLCS changed slightly as the standard developed. The initial PLCS intent, reflected in the logo, was to address four major business functions:

- Configuration Management

- Support Engineering

- Resource Management

- Maintenance Management

Two changes were made as the program progressed. For most complex products, where safety is an inevitable concern, Configuration Management is the bedrock of through life information management. It was however noted that the information set which requires assurance through life is far larger than that addressed by the (then) existing Configuration Management systems. The information set extends beyond the product design to include information about individual products and the large set of assured support data previously made available as technical documentation, parts catalogues, training material and other information. All of this needs to be related to individual product assemblies if safety and efficient support are actually to be delivered. The first function was therefore extended to "Manage product and support information" with the Configuration Change Management process at its heart.

The second major change concerned the relationship to the Supply Chain.

As work proceeded it became apparent that "resource management"

was just one aspect of a wider supply chain process. Several recognized

transactional messaging standards already existed to address supply chain

requirements notably

OAGIS 9.0 ,

RosettaNet

,

RosettaNet and

ebXML

and

ebXML and a number of

domain specific capabilities such as Exostar and Covisint. It was therefore

decided to limit the PLCS scope to the generation of a supply demand

which is a natural output from maintenance planning - and the receipt of

a supply response. This decision has been vindicated by subsequent

events as PLCS and OAGIS 9 have recently been selected by UK MOD

as the primary standards of choice for future logistics information.

and a number of

domain specific capabilities such as Exostar and Covisint. It was therefore

decided to limit the PLCS scope to the generation of a supply demand

which is a natural output from maintenance planning - and the receipt of

a supply response. This decision has been vindicated by subsequent

events as PLCS and OAGIS 9 have recently been selected by UK MOD

as the primary standards of choice for future logistics information.

PLCS has three main components:

- the business vision,

- an Activity Model; and

- an information model.

The business vision has been briefly outlined above. The key concept is the creation, of a single source of truth for assured product and support information, for use across the enterprise. This information will necessarily be created in many different IT systems CAD, MRP, ERP, FMECA, LSAR and authoring tools etc. but, to realize the vision in full, the information needs consolidation to create the necessary explicit links between related items.

This business vision is important because it enables a major improvement in quality and efficiency over typical practice. Currently, some point-to-point exchange capabilities have been established, but the information required to deliver efficient support typically exists in many different IT systems, used by many organizations for different business functions across different life cycle phases.

Particular difficulties are often found in the gap between the OEM and end-user communities, neither of whom have appropriate access to information created by the other. As a result, information which already exists either has to be re-generated, re-formatted or re-entered manually with a proliferation of errors over time, or managers are forced to make decisions based on incomplete or inaccurate information. The impact of information errors and omissions is rarely measured by accountants, but such errors add heavy costs and time delays to many business processes.

The second component is the activity model which illustrates the processes and information flows in the PLCS scope. This provides context for potential data exchanges through life, and can be used to identify information interfaces across any chosen functional boundary. Both the vision and the activity model have "informative" status in ISO. Neither is offered or recognized as a basis for claiming "PLCS compliance".

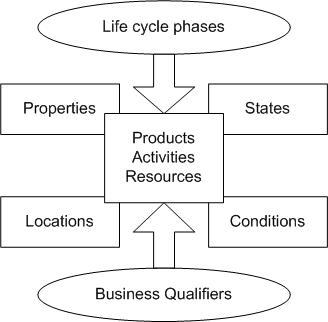

The third and major component of the standard is the Information Model. Written in EXPRESS - the formal data modelling language used by STEP - but also available as an XML Schema, it provides a comprehensive, generic and extensible data model which identifies the key entities, attributes and relationships needed to deliver the PLCS vision. The key concepts in the PLCS information model are shown in Figure 3

This is a very high level view.

The PLCS Concept model gives a more specific view of the concepts that PLCS can support.

gives a more specific view of the concepts that PLCS can support.

Because the model is generic, it must also be extensible. A maintenance task, for example, is modelled as a type of "activity", linked to required resources. By re-classifying the activity as "operational" the same constructs can be used to address product usage or other operational activities, even though these extend beyond the scope of the activity model.

In assessing the potential value of ISO 10303-239 to any given business it is important to recognize that:

- improving information management capabilities using STEP is a well-established approach which has already delivered major cost savings and dramatic reductions in process times in a variety of industrial contexts;

- PLCS is a key enabler for Performance Based Logistics or Through Life Capability Management;

- many opportunities exist for the tactical exploitation of PLCS, which need not necessarily be constrained by wider standardization objectives.

In terms of tactical exploitation, four opportunities are typical:

- Use the ISO 10303-239 Activity Model, and the PLCS Vision, as part of existing business improvement initiatives to improve life cycle support;

- Use the ISO 10303-239 information model to clarify requirements for the development of consistent IT systems interfaces, by comparison of equivalent concepts;

- Use the information model to automate selected interfaces;

- Develop pilot implementations to demonstrate the viability and the value of the integrated Assured Product and Support Information concept.

Realizing the full PLCS vision across any large enterprise will require sustained investment over several years. Maximum return may be expected when;

- the product needing support is complex, with multiple design options;

- the support needs or support environment are complex;

- the product design, support or usage scenarios are subject to frequent change.

PLCS can help your business deliver:

- Reduced Cost of Ownership

- Users of products are seeking improved availability, reliability, maintainability and lower cost of ownership

- Sustainable Business Growth

- Companies are seeking to make money through the life cycle support of their products to improve profits, improve quality and respond quickly to ever-changing customer requirements

- Protection of investment in product and support data

- Users of information systems want more open platforms to reduce IT costs and ensure longevity in use of information

The standards, tools and technology for delivering the PLCS Vision are now in place.